Project WEiTeR – Strategy for hydrogen containers at end-of-use: from extended use to high-quality carbon fiber tape recovery

Hydrogen as an energy vector is a central component of the strategy to reduce CO2 emissions in Germany. Particularly in the traffic and transportation sectors, this energy carrier offers the possibility of replacing fossil fuels. In terms of hydrogen storage, carbon-fiber-reinforced pressure vessels (CFRP tanks) are currently state of the art. Due to the energy-intensive manufacturing process of carbon fibers, a sustainable strategy for the end-of-use of hydrogen tanks must already be developed today.

The aim of the WEiteR project is to establish a Freiburg competence center for the evaluation of CFRP hydrogen tanks during operation and at end-of-use. Fraunhofer EMI and IWM as well as INATECH are involved in this project. As part of the project, solutions for extending the service life, reuse and high-quality recovery of the embedded carbon fibers – taking into account the aging of the materials used – are being developed and made available to industry.

During the service life, innovative methods for tracking and predicting the material properties are being developed based on monitoring the tanks. Depending on the scenario, this should enable an extension of the lifespan or qualification for a different application.

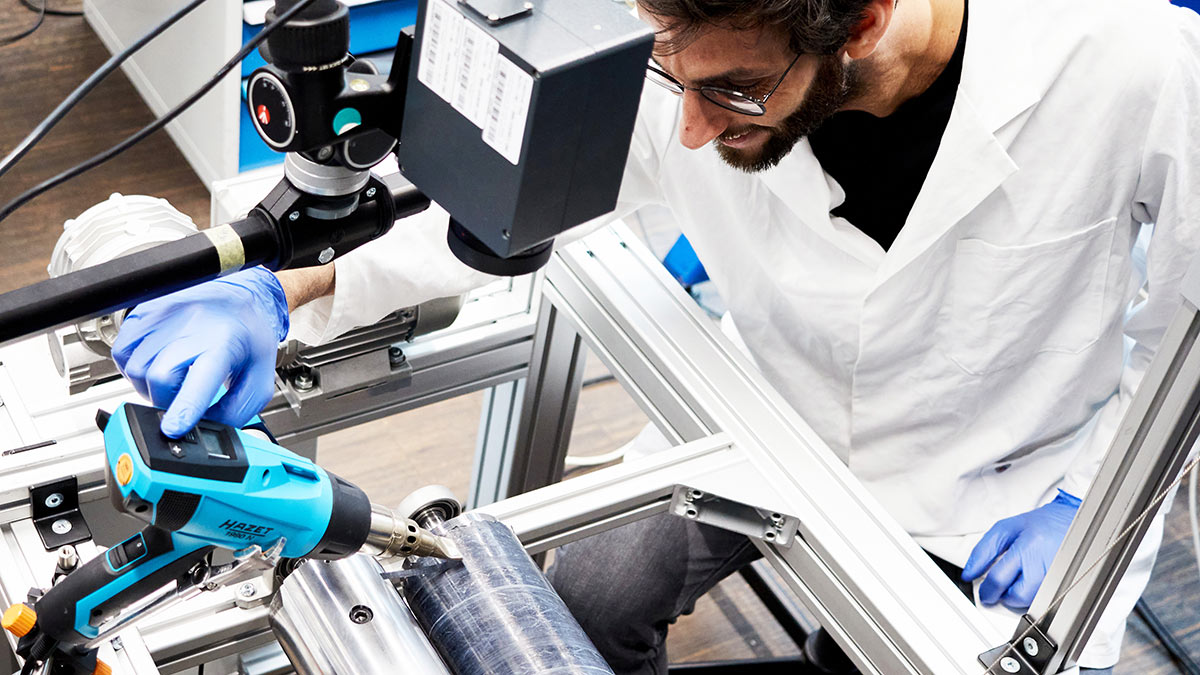

New recycling process

In addition, an innovative peel process for recovering the carbon fiber tapes without significantly shortening the fibers is being investigated and numerically modelled. This strategy differs significantly from current fiber composite recycling processes, which systematically include a shredding stage and thus lead to downcycling of the material. In contrast, the project results have shown that under suitable thermo-mechanical peeling conditions, the continuous fiber reinforced tapes can be recovered with retained mechanical properties. Accordingly, after recycling, they are available for a reuse in highly demanding applications.