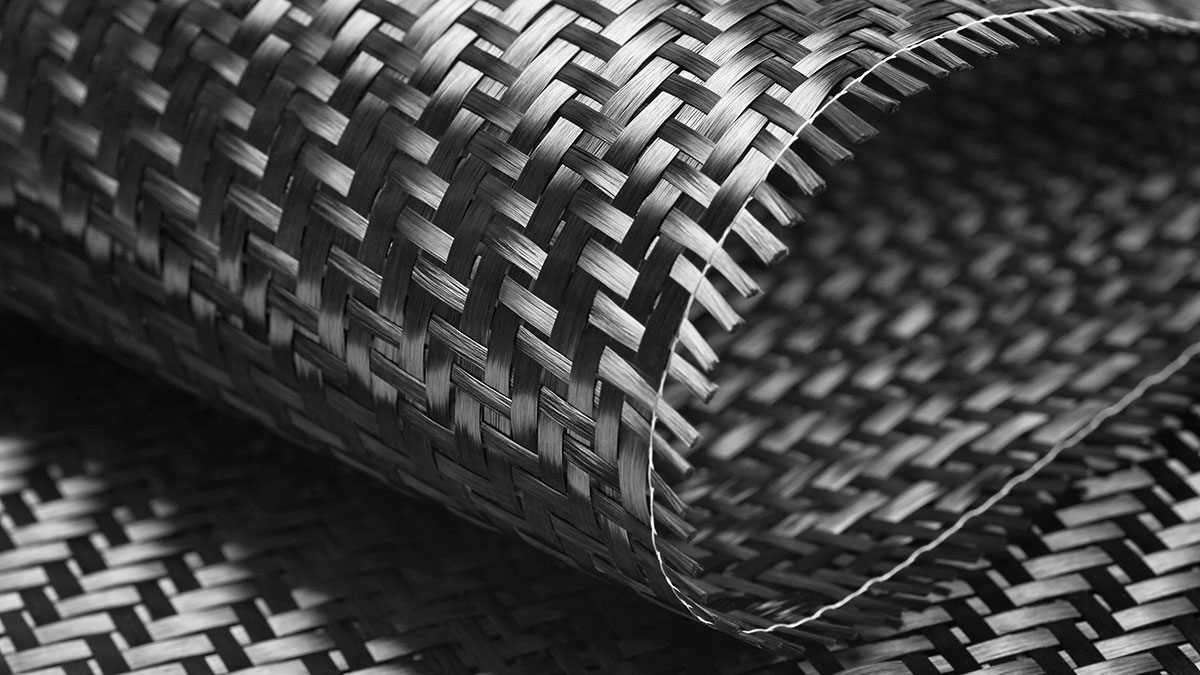

Project: DigiTain

Application of laser technology for recycling hydrogen tanks made of carbon fiber reinforced plastics.

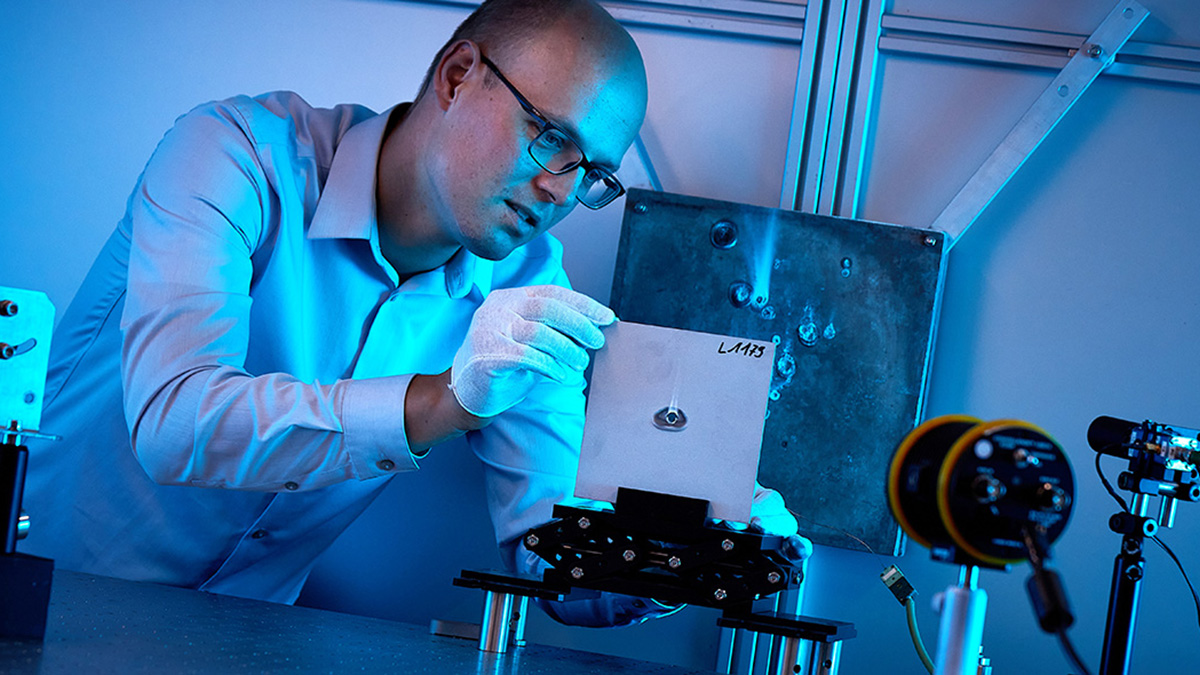

Project: Laser safety quantitative risk analysis

Software tool for assessing the security of free-field laser applications

Project: Topology optimization for multidisciplinary design problems

Software solutions and research service for industry.

Project: Expert tool laser effect

Investigation of fundamental interaction processes of high-energy laser radiation with matter and development of predictive computer models.