Opening up a new dimension with X-ray

Highly-dynamic X-ray with 1000 images per second

The technology makes it possible for the first time to experimentally validate the behavior of internal components and subsystems during the test.

Highly-dynamic X-ray with 1000 images per second

The technology makes it possible for the first time to experimentally validate the behavior of internal components and subsystems during the test.

Direct observation of critical processes

Until now, these processes could only be measured indirectly (e.g. using acceleration sensors) or reconstructed after the experiment. Highly-dynamic X-ray enables the direct observation of critical processes.

Millisecond-precise analysis and data feedback into the familiar working environment

The critical point in time at which a system tilts can be compared with the FE simulation with millisecond precision. If prominent areas in the X-ray image are tracked over time, it is possible to transfer the trajectories back to the evaluation software.

Linking design, process and material

The material is analyzed before, during and after the processes. By digitally linking design, process and material, solutions can be determined reliably and with maximum precision.

Can you X-ray a car – just like a doctor?

And all this in a high-speed collision?

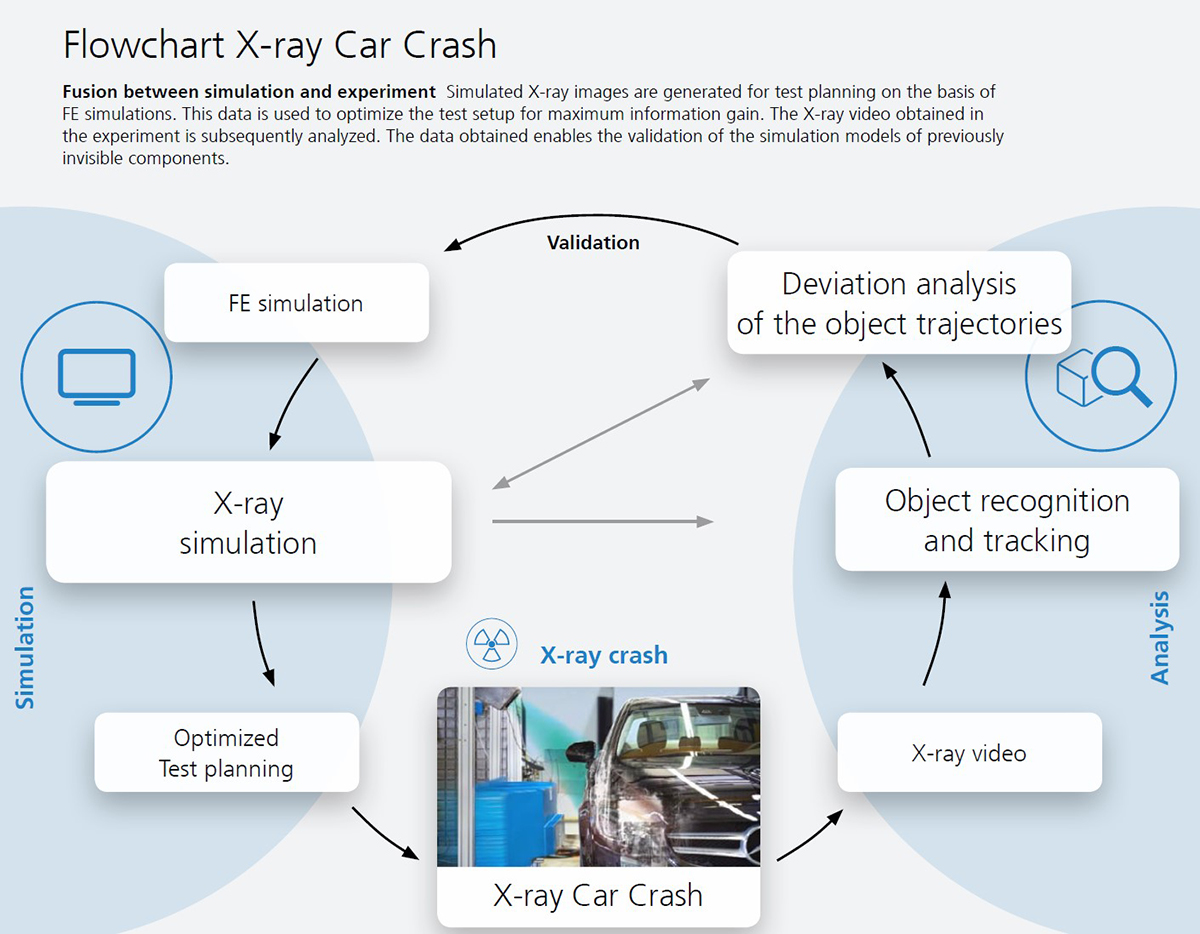

At the Fraunhofer EMI research crash-test facility, a highspeed X-ray video is created during the vehicle crash.

Using a priori data and simulations, defined areas and specific components inside the vehicle are examined in advance.

If FE simulation data is available, virtual preliminary tests can be carried out using the X-ray simulation developed in-house. This allows the experimental setup to be optimized. The observation window in space and time must be defined in such a way that important processes take place as transversely as possible to the direction of observation.

Markers are used for special questions – similar to those used in medicine. They are particularly easy to recognize in the X-ray image after imaging. Under these conditions, the results can be evaluated precisely.

An X-ray video is generated from the raw data using digital image processing algorithms. It is processed in such a way that internal processes can be easily understood. In addition, digital pattern recognition techniques can track features and record their trajectories quantitatively.

Impact tests at component and overall vehicle level with impact masses of up to 3 tons and speeds of up to 80 km/h are carried out in the research crash facility.

The relevant processes in experiments often take place hidden inside. There are many reasons for this: complex component structures, overlapping multi-level protection concepts or cladding. With all these limitations, highly-dynamic X-rays provide a direct insight.

Accurate detection of the head position – despite airbags

A large number of airbags are deployed during the crash test of modern vehicles. The curtain airbags in particular block the view of the dummies inside the vehicle. Acceleration sensors, interior cameras and color markings only provide an incomplete picture. Highly-dynamic X-rays can be used to film the exact position of dummies in the vehicle: How close has the head really come to the steering wheel? Are there elastic deformations that are no longer recognizable after the crash?

X-rays provide answers about the crash sequence

In the MPDB test, the front end of the car penetrates deep into the honeycomb barrier. During the evaluation, the plastic deformation is measured with millimeter precision after the crash. But how deep does the vehicle penetrate and when? When does deformation occur in the crash structure in the barrier? How large is the maximum elastic deformation? X-rays can provide answers to these questions.

Investigate impact at the time of deepest intrusion

When protecting VRUs or occupants, dummies come into contact with multi-layered complex structures such as the A-pillar. Both outer layers and inner structures deform in the process. However, elastic deformation of the deeper structures or when failure occurs can no longer be detected after the test. Highly-dynamic X-rays can be used to examine the impact at the time of the deepest intrusion and to clarify the relevant issues.