Together with Mercedes-Benz, Fraunhofer EMI has carried out the world’s first X-ray crash – with 1000 X-ray images per second.

What exactly happens during a crash? When does the crash-absorbing structure fold? Does the A-pillar and occupant dummy interact? How deep does the dummy head penetrate into the airbag and how close does it come to the hard structures?

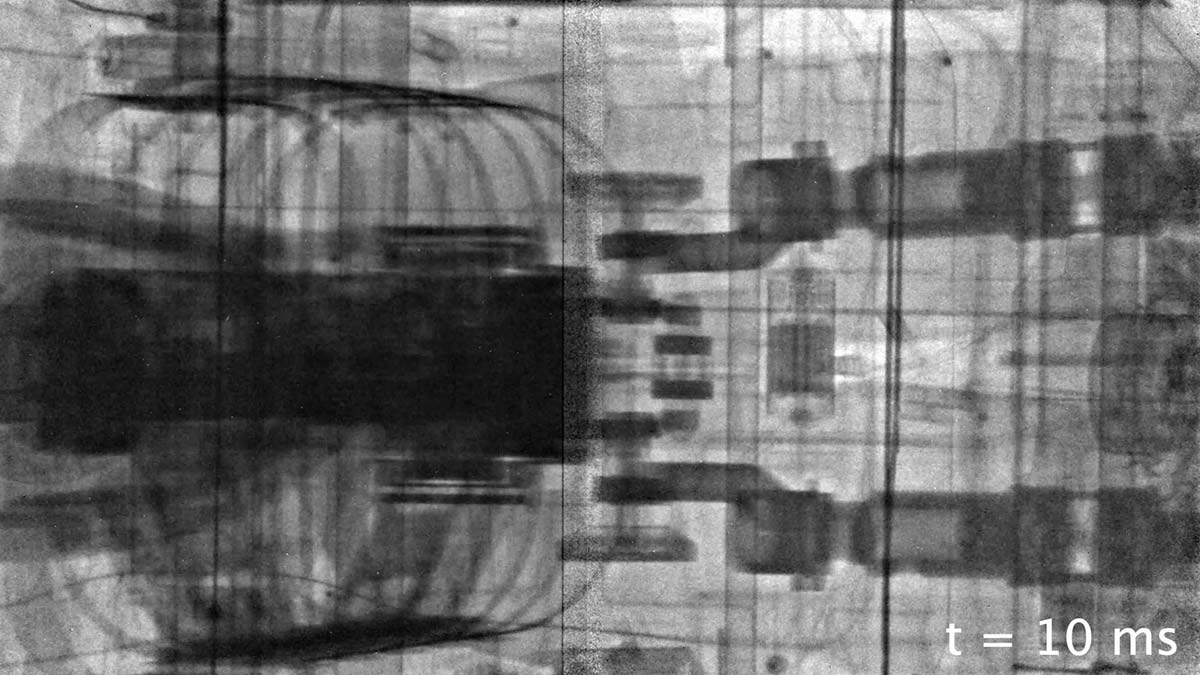

These important questions are to be answered in a crash test using a large number of sensors and high-speed cameras. A completely new type of technology has now been added that can visualize previously invisible deformations and their exact sequences in high resolution: Together with Mercedes-Benz, Fraunhofer EMI has carried out the world’s first X-ray crash with a passenger car. Fraunhofer EMI uses a linear accelerator as an X-ray source and combines it with a high-speed detector. This makes the relevant areas inside a vehicle visible with a high temporal resolution of 1000 images per second and high X-ray energies of up to 7.9 million electron volts.

In order to protect the researchers and the environment from this radiation, extensive radiation protection construction measures had to be carried out at Fraunhofer EMI crash hall. In addition to the physical shielding, a complex technical safety concept was developed and implemented that combines radiation protection on the one hand and the necessary flexibility for research operations on the other in the best possible way.

The test in detail

The first X-ray crash was a side impact with an MPD barrier. The barrier hit a C-Class sedan at 60 km/h vertically from the side. A female dummy optimized for the side impact was sitting in the driver’s seat inside the vehicle. In the dummy, in the vehicle and in the crash hall, dozens of measurement channels recorded accelerations, speeds and high-speed videos. The X-ray crash technology monitored the area of the dummy in the driver’s seat. Underneath the vehicle was a 40 cm x 80 cm X-ray detector, which was developed together with the Fraunhofer EZRT. The linear accelerator, weighing more than 2 tons, was positioned under the hall ceiling. Held by counterweights, the linear accelerator floated on a linear-guided XY table. This ensures maximum clearance for the crash below the X-ray source and at the same time highly accurate positioning of the focal spot.

Synchronous to conventional measurement technology, 1000 X-ray images per second were taken during the crash test. The design of the X-ray experiment, based on many years of research, enabled a precisely planned view of the internal dynamics of the crash test that had never been visualized before. Shortly after the impact, the incipient deformation of the side of the vehicle can be seen. The deploying airbags prevent conventional cameras from obtaining a detailed view of what is happening inside the vehicle.

In-depth insights through X-rays

However, the movement of the dummy’s left arm caused by the protective airbag can be seen in the X-ray image. As the experiment progresses, the increasing load on the dummy’s torso becomes visible before the vehicle’s protective structures finally absorb the impact and secure the vital protective space.

This now accessible information enables a deeper understanding of the complex interaction of the dummy with the restraint systems and allows targeted further development of the safety technologies in the vehicle.