Safety for all road users

The traffic of the future presents us with major challenges: Increasing automation, an increasing proportion of battery electric vehicles and the multimodality of traffic.

The traffic of the future presents us with major challenges: Increasing automation, an increasing proportion of battery electric vehicles and the multimodality of traffic.

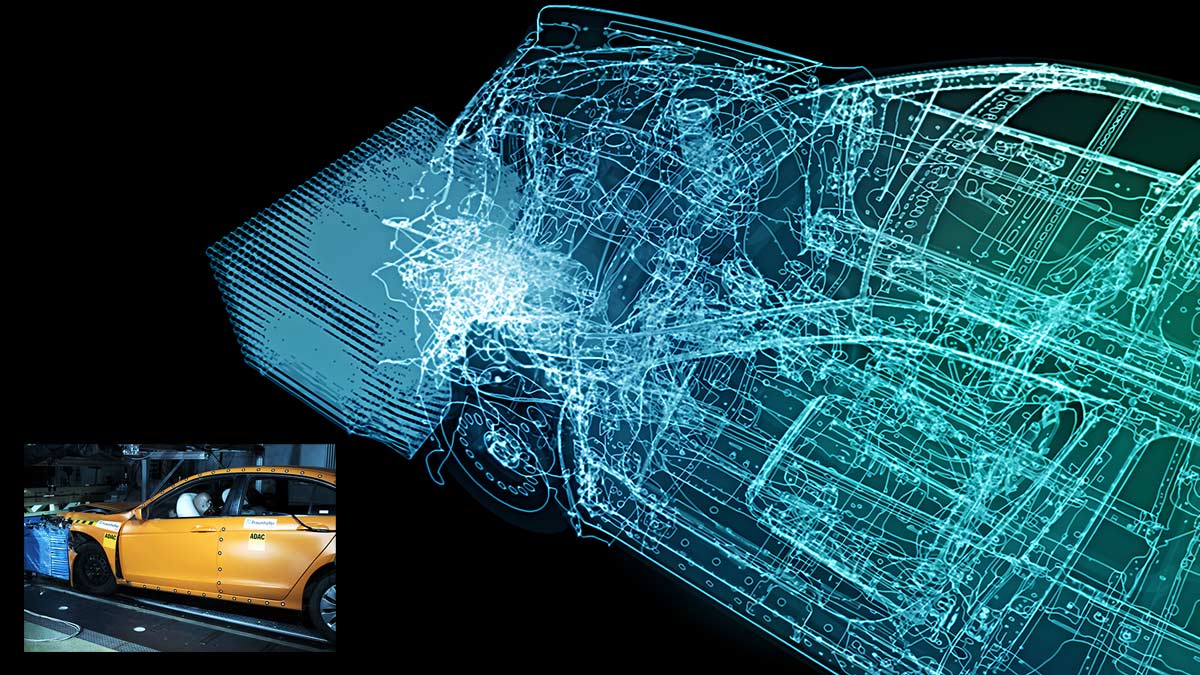

The central topics of the business uegment Automotive are the mechanical characterization and numerical modeling of modern materials, composites and components under static, shock, and impact loading. The possible applications of the examined materials range from safety-relevant components for crash loading in the automotive field to structures that are exposed to extreme deformation velocities during impact processes in the aerospace sector.

In material characterization, methods for micro- and nanostructure analyses are increasingly used alongside standardized, nondestructive and destructive test methods. Especially the use of acoustic microscopy and micro-computed tomography foster research on the characteristics of relevant materials up to very small length scales. This is necessary because in materials, many relevant processes that decisively influence macroscopic behavior (e.g., in case of car-crash loading) take place on the micro- and nanoscale. The experimental portfolio is complemented by special facilities for material characterization at high deformation velocities. For example, a test bench for the examination of the crashworthiness of electric vehicle batteries and a component crash-test facility yield important findings for the structural design of modern vehicles.

The second topic of interest is numerical modeling. In this process, mathematical equations, mostly based on the experimental results gained from material characterization, are applied in numerical simulations. In the simulation, these equations reproduce the physical behavior of the respective material under different types of loading. Especially the fast development of new materials and the necessity to understand their behavior in case of complex loading without having to conduct elaborate experiments illustrate the importance of material modeling. To realize this, both commercial simulation software such as LS-DYNA, PAM-CRASH, ANSYS Autodyn and ABAQUS as well as SOPHIA, a software developed at EMI, are used. The combination of experimental material characterization and numerical modeling allows to carry out predictive and reliable simulations of crash and impact scenarios concerning components and structures.